ERP for Supply Chain Management

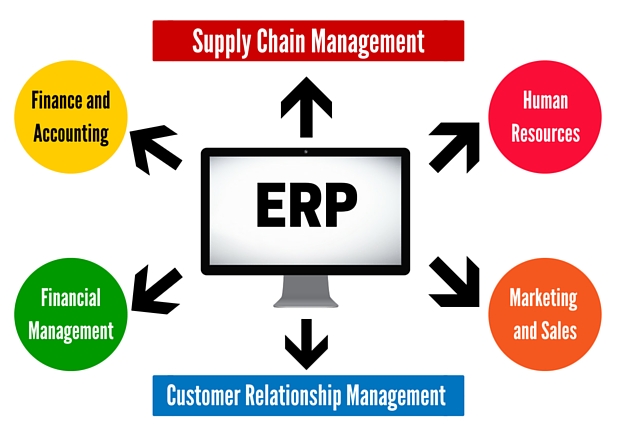

Over the past few decades, businesses have been using smart business automation software to gain operational efficiency, enhance productivity, and achieve profitability. With time, businesses evolve and they need to adapt to various changes in market scenario to remain agile. To this end, businesses need to automate and streamline their operations across various departments and functions such as finance, accounting, human resources, production, material management, quality management, distribution, and sales. Organizations use Enterprise Resource Planning (ERP) software to manage business information, integrate various disparate systems, streamline workflows, and achieve efficiency.

Supply Chain Ecosystem

Supply chain ecosystem typically consists of manufacturers, suppliers, distributors, retailers, and customers. Supply chain management (SCM) involves planning, execution, control, and monitoring of supply activities. An ERP solution takes care of physical aspects of supply that includes storage and transportation and the market aspect of effectively managing demand and supply to meet customer demands. Feature-rich ERP software adds value to the entire chain starting from material procurement to end- customer product delivery. An efficient ERP solution coordinates and integrates three key flows: material flows, information flows and financial flows.

ERP as an integral part of Supply Chain Management

Supply chain management has been an integral part of ERP solutions adopted by several enterprises. Manufacturers need to interact with various suppliers and partners to obtain the raw materials and resources at the right time and at the right amount to bring finished goods to market. Businesses are actively focusing on several supply chain strategies to boost plant productivity, enhance product quality, and cut down on manufacturing costs. As the operations become more extensive and globalized, the integration of SCM becomes all the more important. ERP solution can support multiple modes, such as make-to-order, engineer-to-order and configure-to-order and provide operations support across multiple sites in real time. ERP solution streamlines the path their products go through from supplier to warehouse and finally to store for customer. As a result, businesses can avoid supply chain disruption.

Role of ERP in Supply Chain Management

1. Demand and planning

An ERP system meant for supply chain management can automatically create demand when orders are received. ERP streamlines supply chain management by creating effective job scheduling. As a result, supervisors can know in real time what resources are being consumed and which resources are used. This helps them to plan product delivery dates. Production should ideally begin when inventory and raw materials are full. ERP ensures that production policies are consistent with demand, replenishment is done at the right time, and inventory is lean.

2. Procurement

An ERP meant for SCM offers more effective way to manage procurement and supply of the goods, services, and other resources across the chain. From handling manufacturing and warehouse resources to managing transportation and execution processes, ERP solution takes care of all elements of supply chain. Several manual tasks such as communicating with vendors and suppliers and keeping track of the communications can easily be automated with ERP.

3. Production

The ERP system enables the creation of bill of material (BOM) for each item. After production starts, all records for machine and labor resources are created and updated in real time. All shipping documents are recorded through the ERP system for proper supply chain management, eliminating errors due to manual process. The system can ensure that products are sent out in time which can be delivered on the due date. Feature-rich ERP helps in modifying work orders and job tasks to accommodate all last minute alterations, so that production process is completed on time.

4. Shipment

Once the item has been shipped, the ERP software can create an invoice that has to be finally sent to the customer. An ERP system helps in maintaining a central repository for customer shipments and all delivery details to ensure that items are delivered on time. Furthermore, functionalities in the system helps in deciding packaging methods and set criteria for quality check for both internal and external packages. With the help of ERP, companies can resolve resource conflicts in the task list.